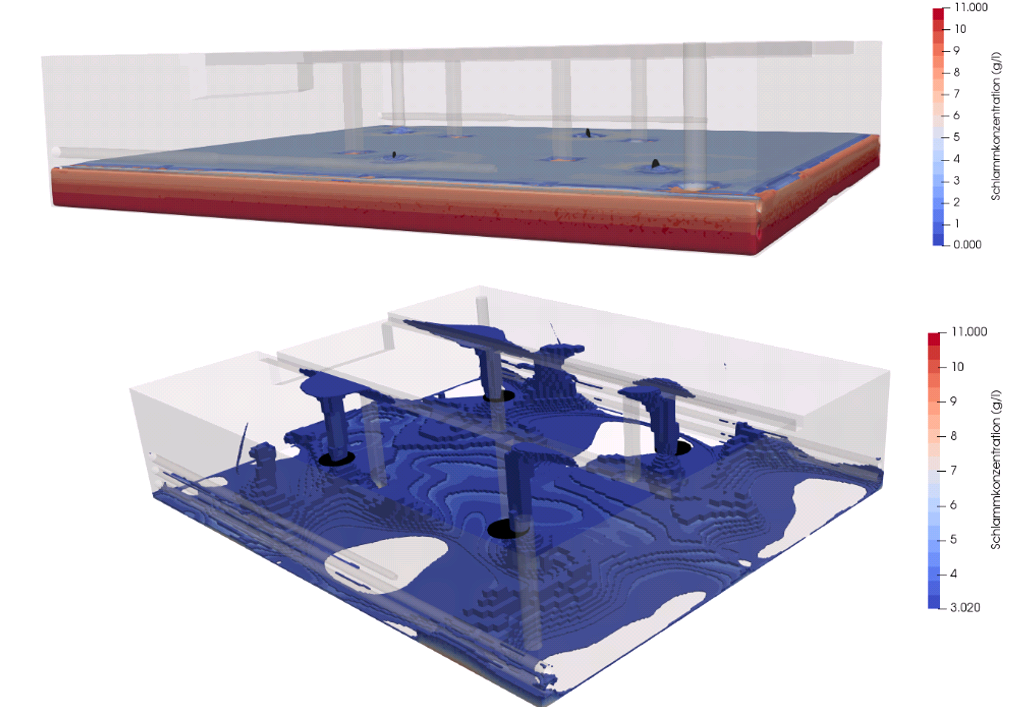

3D-CFD simulation of a Sequencing Batch Reactor (SBR)

Mattias Deller, 15. April 2019

Sludge mixing optimization in a SBR using different stirrer configurations.

In a SBR (Sequencing Batch Reactor) process, the biological treatment and the sludge sedimentation take place in the same basin. The sequence is ensured by a temporal cycle, e.g. filling - mixing - filling - aeration - sedimentation – decantation. An optimal operation mode requires a fast and homogeneous mixing of the sedimented sludge in the water phase by the use of powerful stirrers (mixing process).

TK CONSULT AG was commissioned with the numerical assessment and optimization of different horizontal and vertical stirrers in the SBR. Simulations have been conducted on the basis of so-called drift flux models (a 2-phase code using a mathematical model for the description of the sedimentation rate of the sludge). The parameters of the drift velocity model could be derived from settling test measurements. The evaluation of the different configurations was performed considering the mixing ratio variation over time. The numerical model allows a reliable cost assessment as well as a preliminary validation of the optimal operation conditions.