3D-CFD simulation to optimize the mixing of a digester tank

Deller Mattias, June 14, 2019

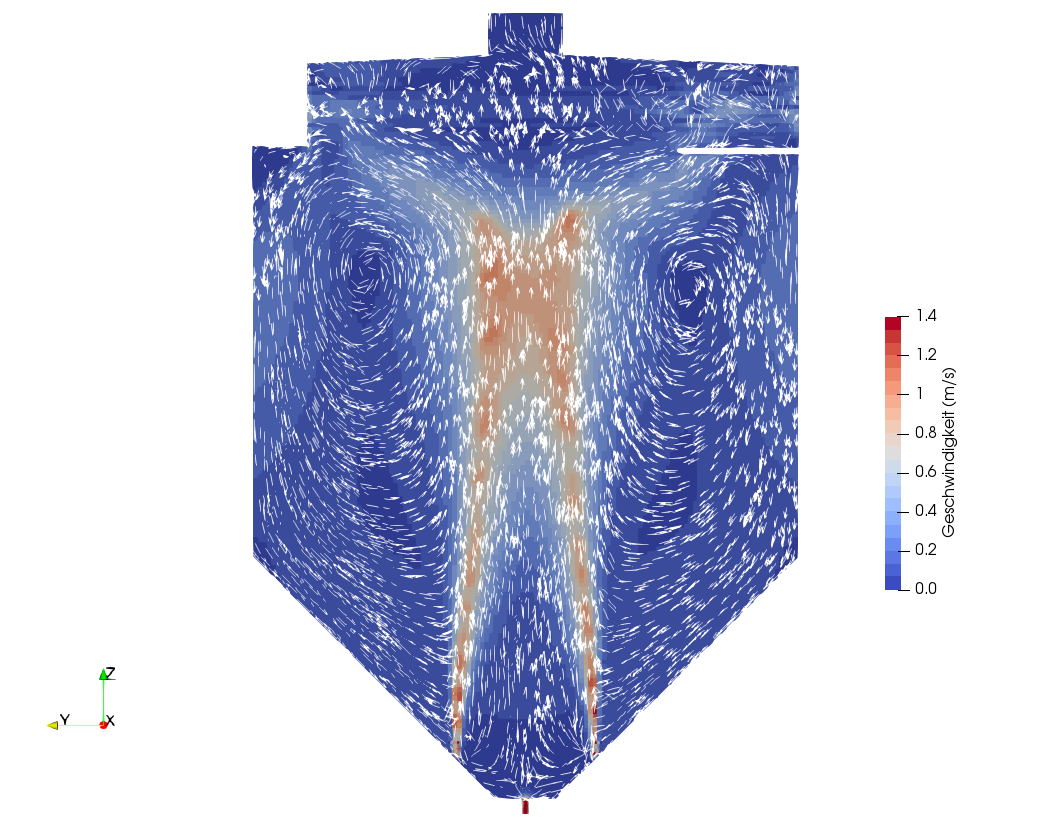

Investigation of the mixing performance in a digestion tank for different gas injection configurations.

The primary sludge collected from the mechanical cleaning stage of a sewage treatment plant is sent to the digester tank for further treatment. In the digester tank, the organic components are biodegraded. The sludge is continuously suspended by stirring and aeration (gas lances / gas pressure lifts). An efficient mixing limits the sludge sedimentation and prevents a longterm reduction of the digester volume.

TK CONSULT AG was commissioned to investigate the mixing performances of different gas injection configurations. By a variation of the gas volume as well as the number and position of the gas lances, the mixing performance has improved. All numerical simulations were based on a 2-phase approach (sludge and gas). Numerical validations represent a reliable cost-effective approach to optimize the configurationg and maximize the efficieny of the investment costs.