Urban Water Management

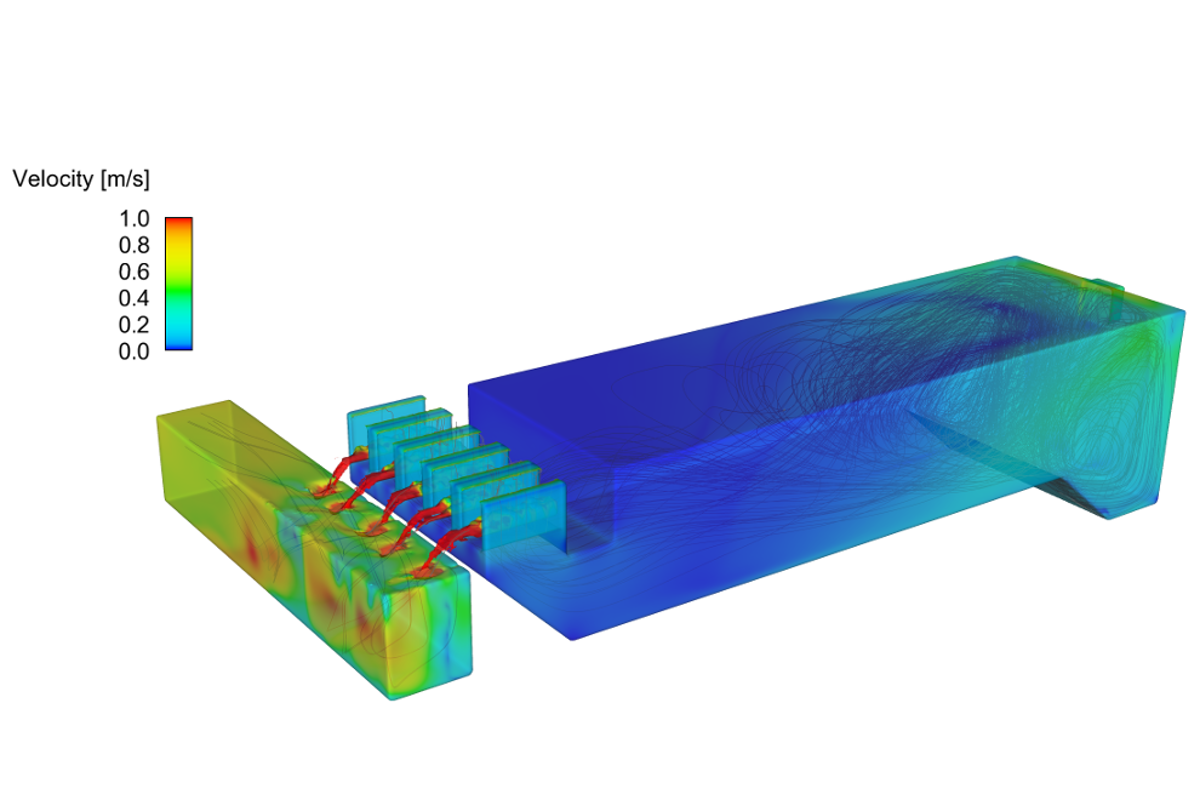

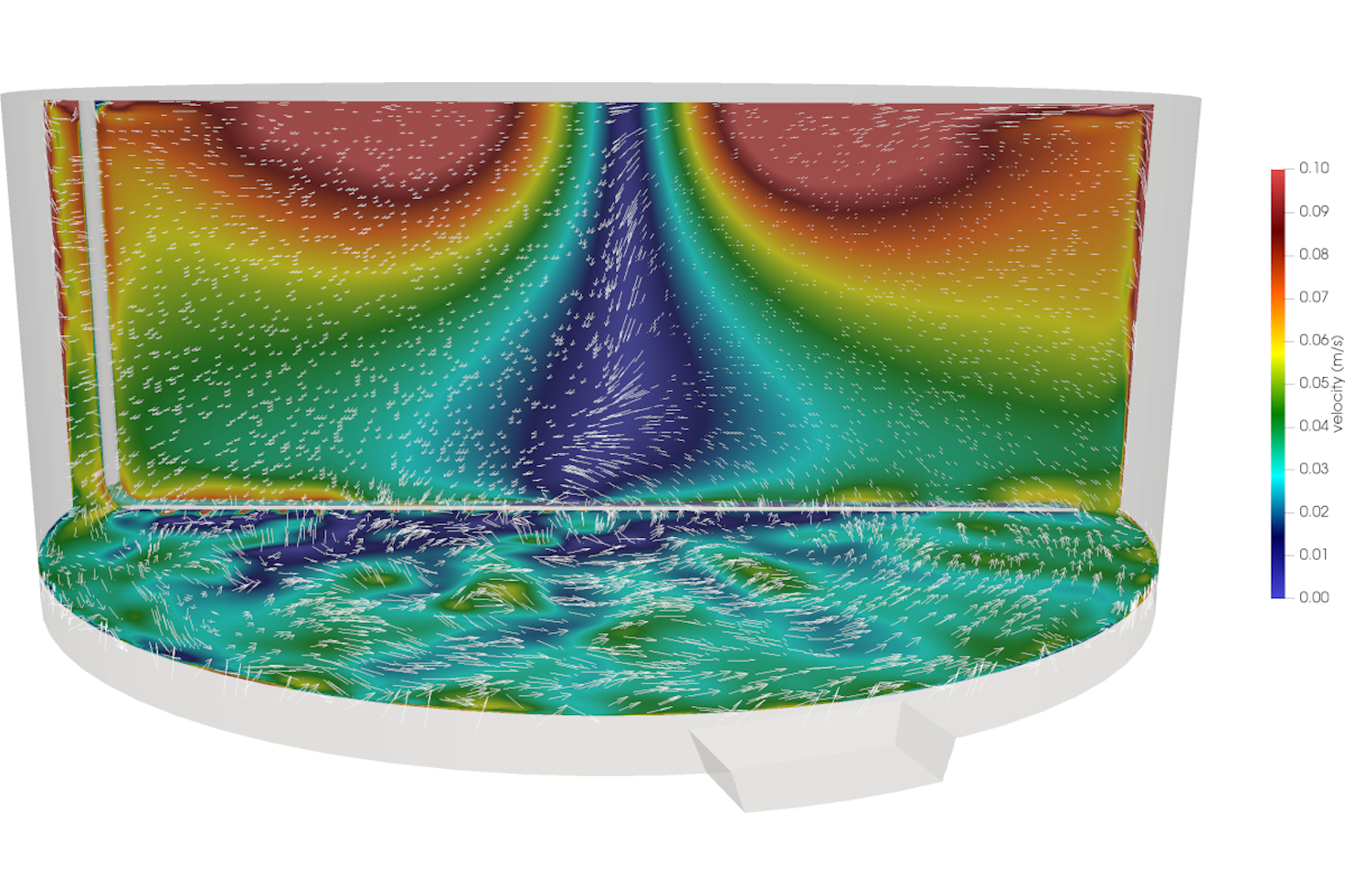

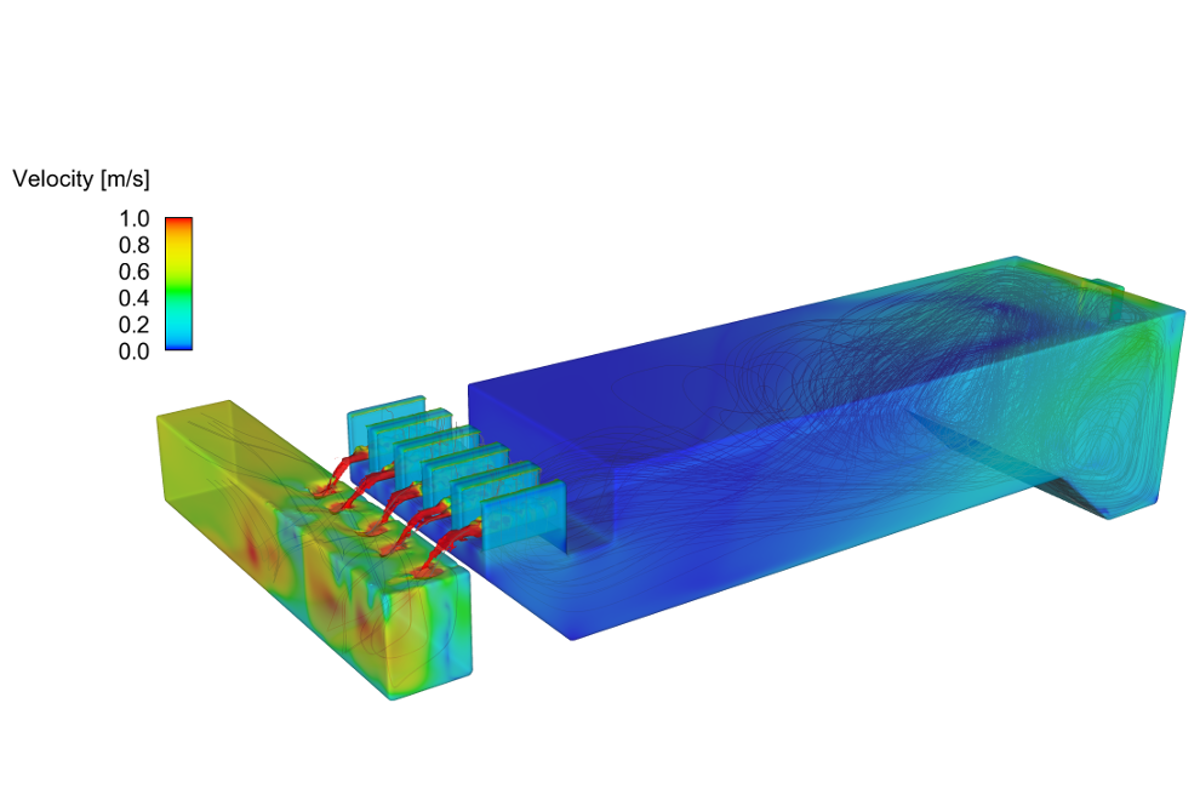

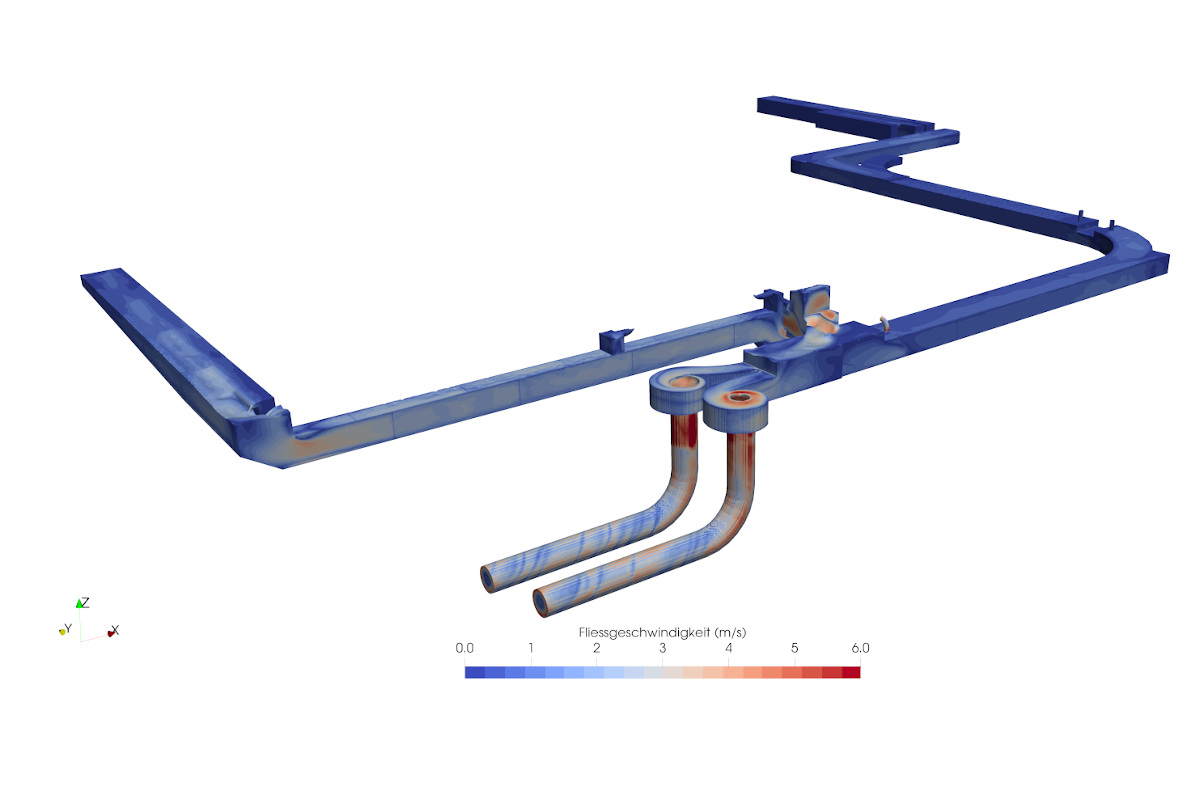

CFD models enable the realistic simulation of complex flow phenomena and with that a cost effective proof of functionality. At the same time, enhanced visualizations of simulation results increase the understanding of the complex processes. Due to the flexible adaptability of numerical models, systems can be easily optimized and improved. This leads to a reduction of construction errors while maximizing the benefit.

Services

- Verification and optimization of special structures (e.g. fall structures, vortex fall shafts, shaft structures)

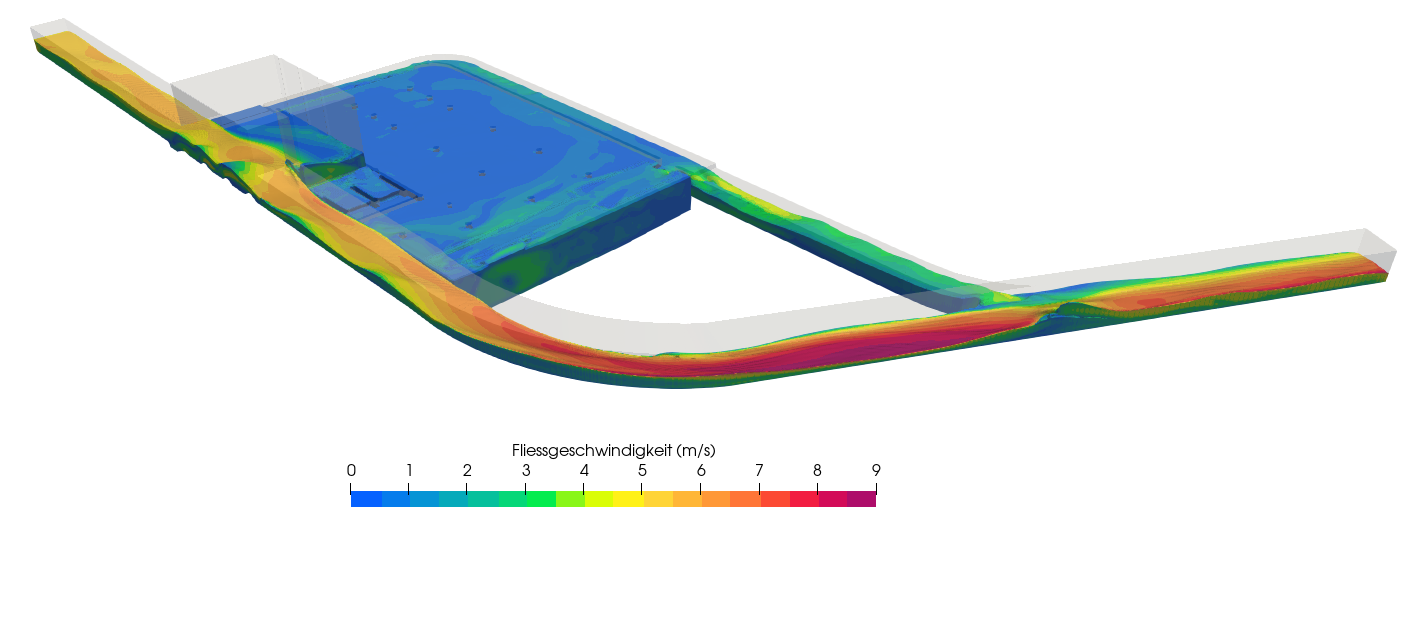

- Verification and optimization of storage channels, flow basins, catch basins, rain overflow basins, rain retention basins

- Assessment of ventilation

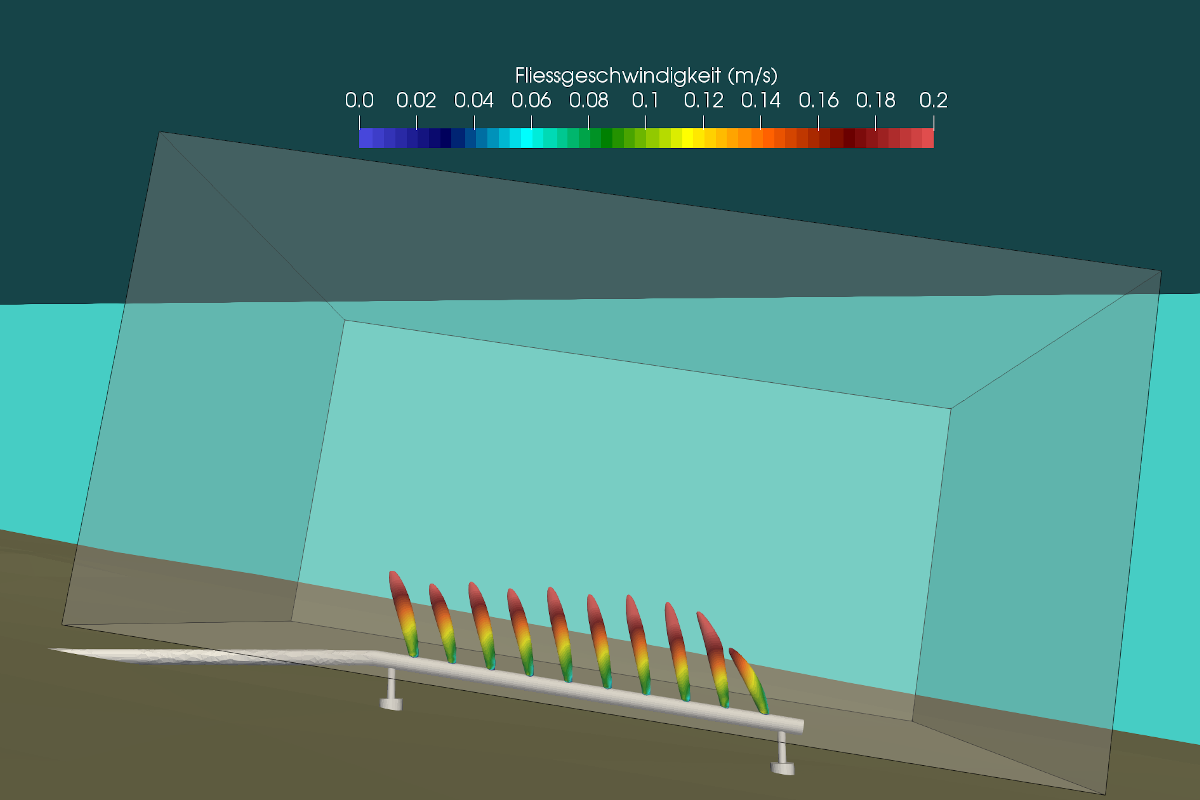

- Verification and optimization of sedimentation tanks (sand traps, primary settling tanks, secondary settling tanks, lamella separators, thickener)

- Verification and optimization of rakes (coarse and fine rake)

- Verification and optimization of activated sludge tanks (denitrification, nitrification, agitators, aeration)

- Verification and optimization of digester (gas lance, agitators)

- Verification and optimization of fourth purification stage (activated carbon reactor, ozone reactor)

- Verification and optimization of special structures (e.g. rakes, pumping stations)

- Assessment of flow conditions in reservoirs (e.g. residence times)

- Verification and optimization of reactors and contact pools (ozone, chlorine, chlorine dioxide, powdered activated carbon, flocculants)

- Assessment of the interference of chemicals and gases

- Verification and optimization of sedimentation tanks

- Hydraulic optimization of all system parts

- Verification and optimization of water distribution and inlets with open filters

Contact person

Michel Kuhlmann

MSc. Env. Science ETH

Head of Division Hydraulics

| E-Mail: | michel.kuhlmann@tkconsult.ch |

| Tel.: | +41 (0) 44 288 81 82 |

Latest News

Andrej Sternin, Michel Kuhlmann, 17. May 2024

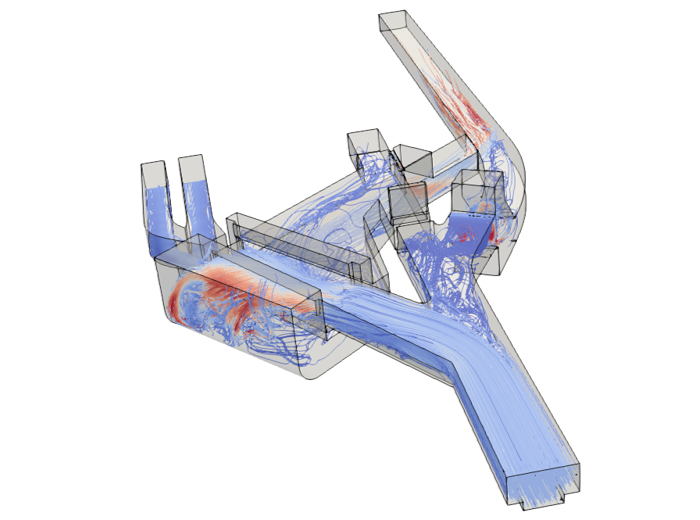

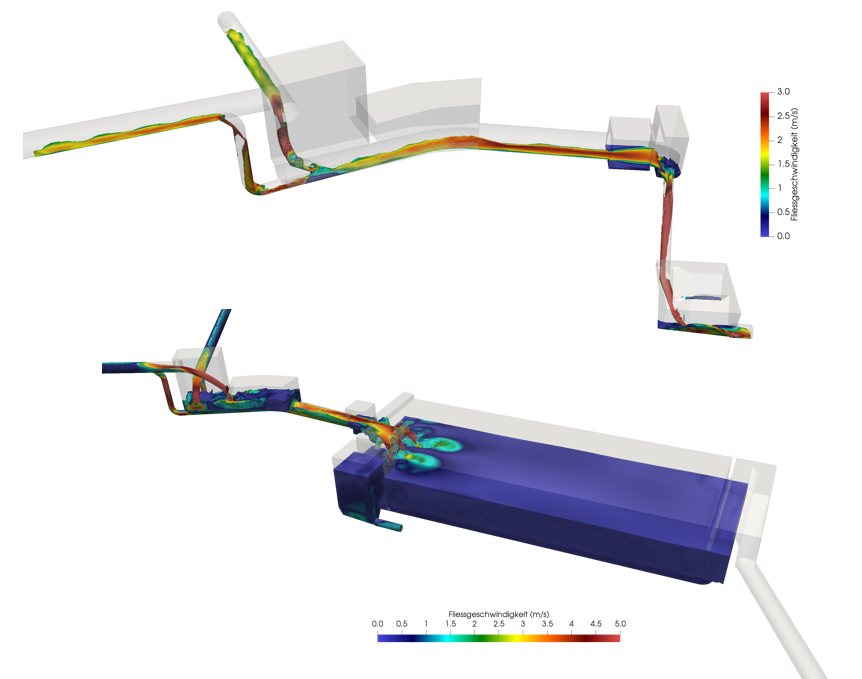

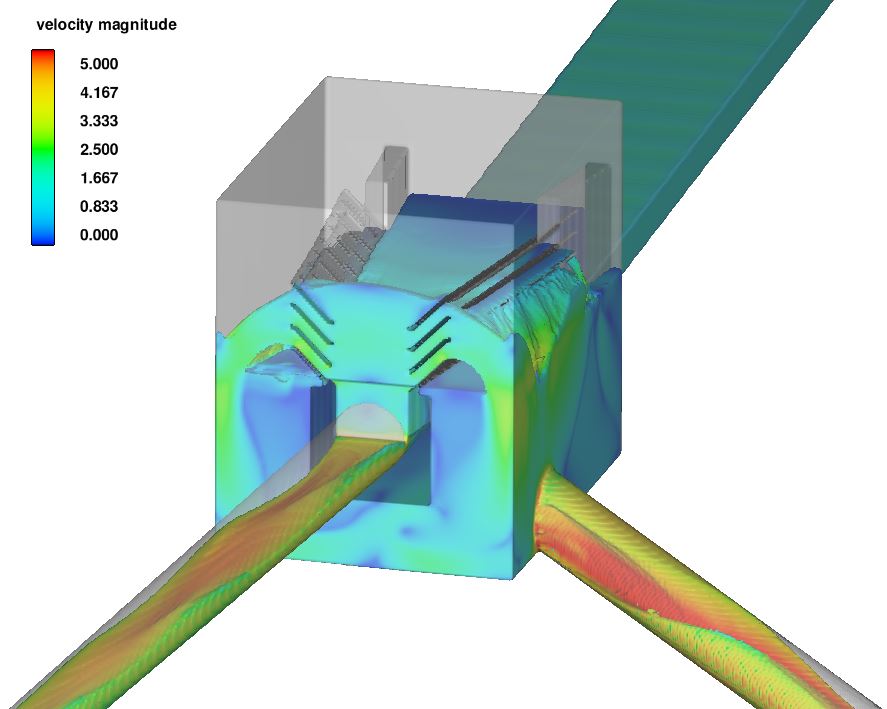

For the expansion of ARA Basel, TK CONSULT AG, together with HOLINGER AG, carried out the hydraulic verification of a distribution structure, developed optimization possibilities, and dimensioned the installations in the distribution structure using numerical modeling.

Read Article

Andrej Sternin, 23 November 2023

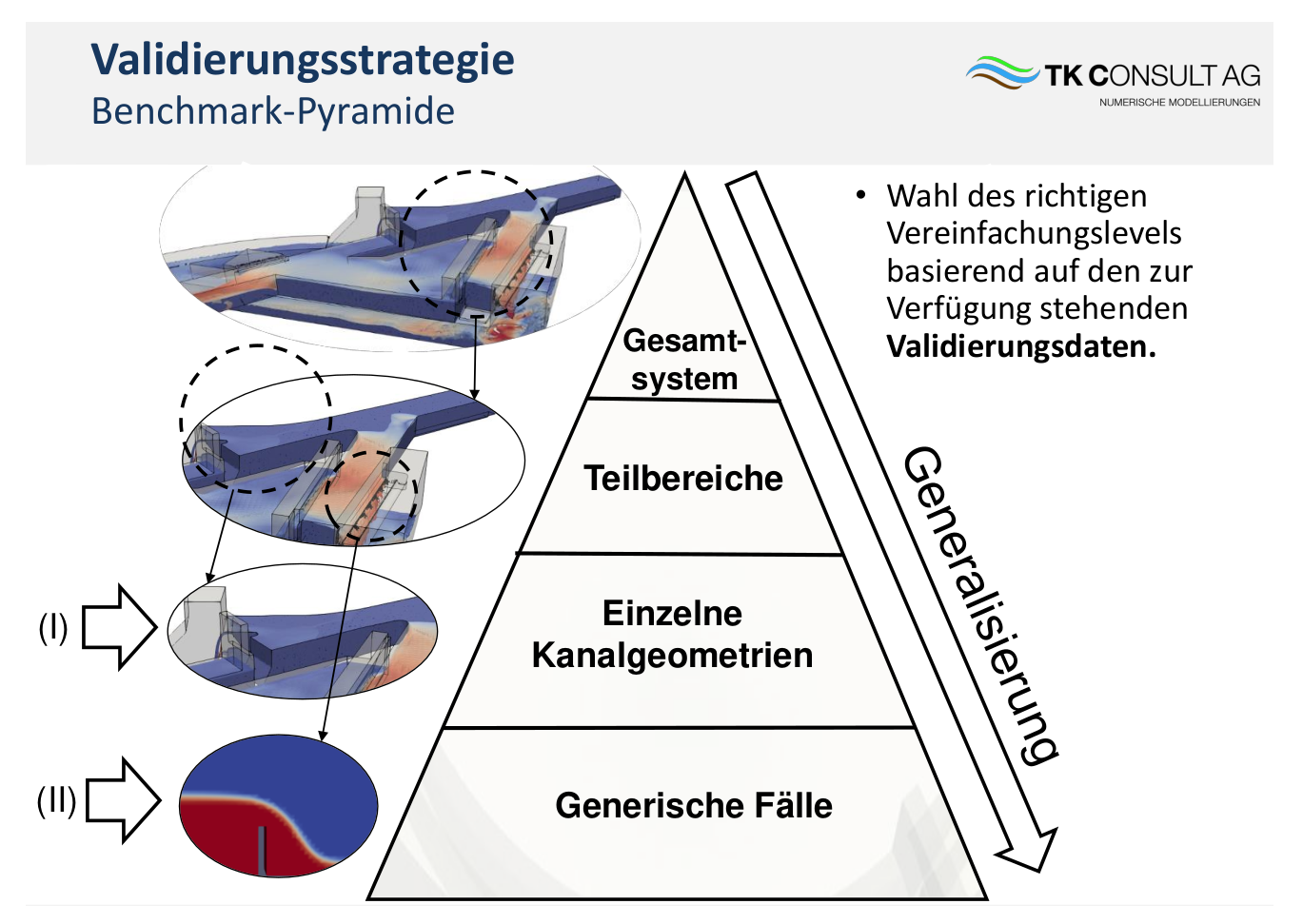

TK CONSULT AG was invited by the VPE/PLM (virtual product development/ product lifecycle management) association to give a presentation on the topic of verification and validation of simulations.

Read Article

Andrej Sternin, 20. September 2023

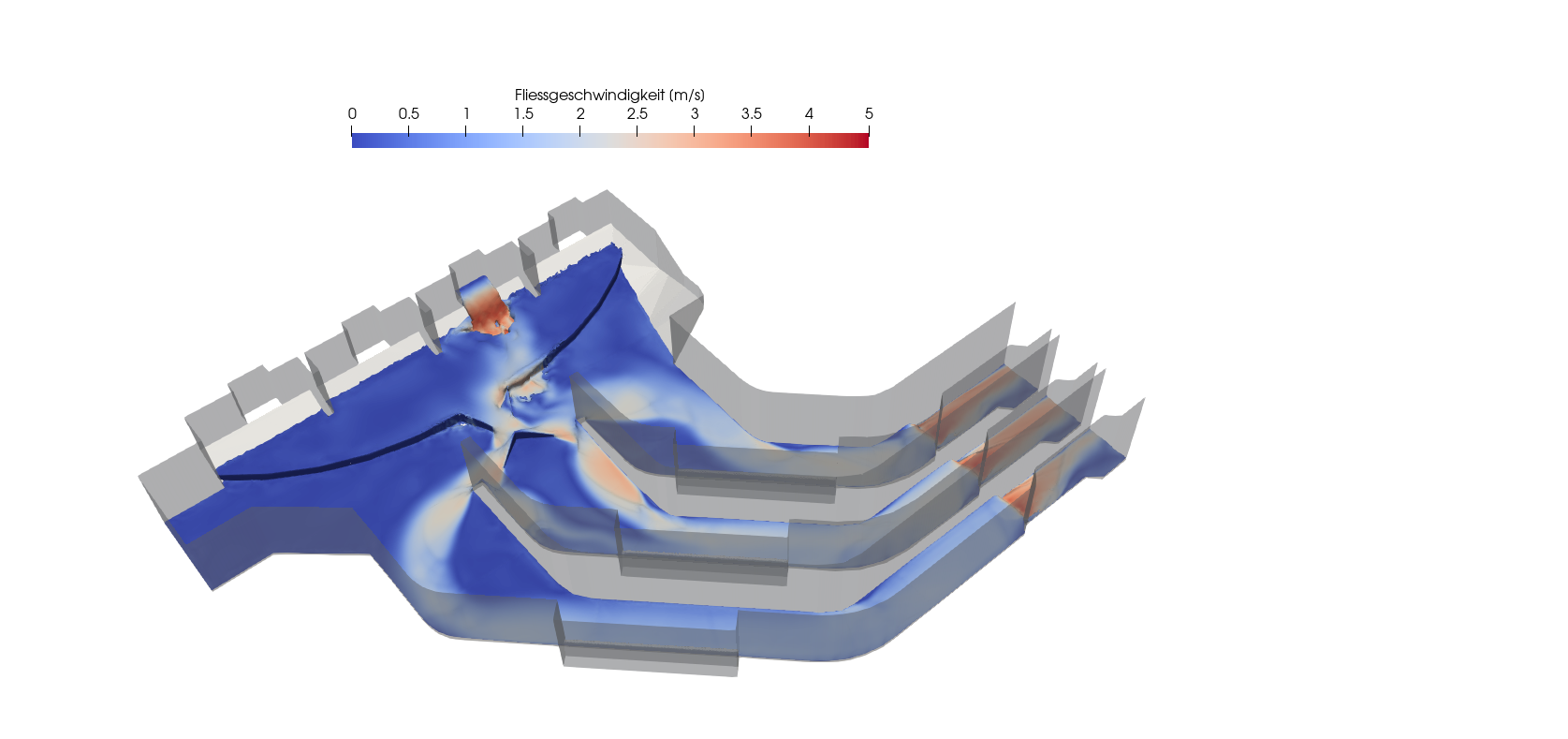

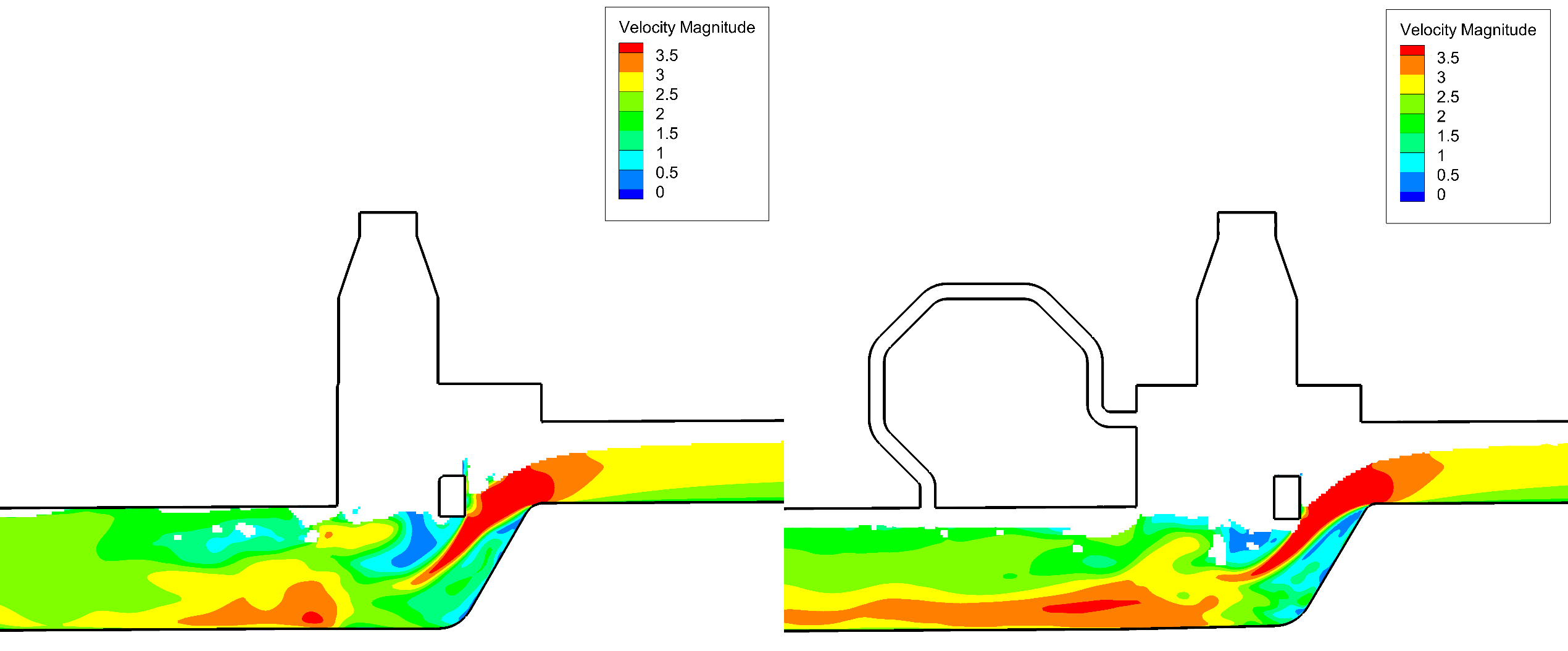

Verification of the safety mechanisms of a sewer system in the event of heavy precipitation by means of CFD simulation

Read Article

Pirmin Ebner, 16. June 2022

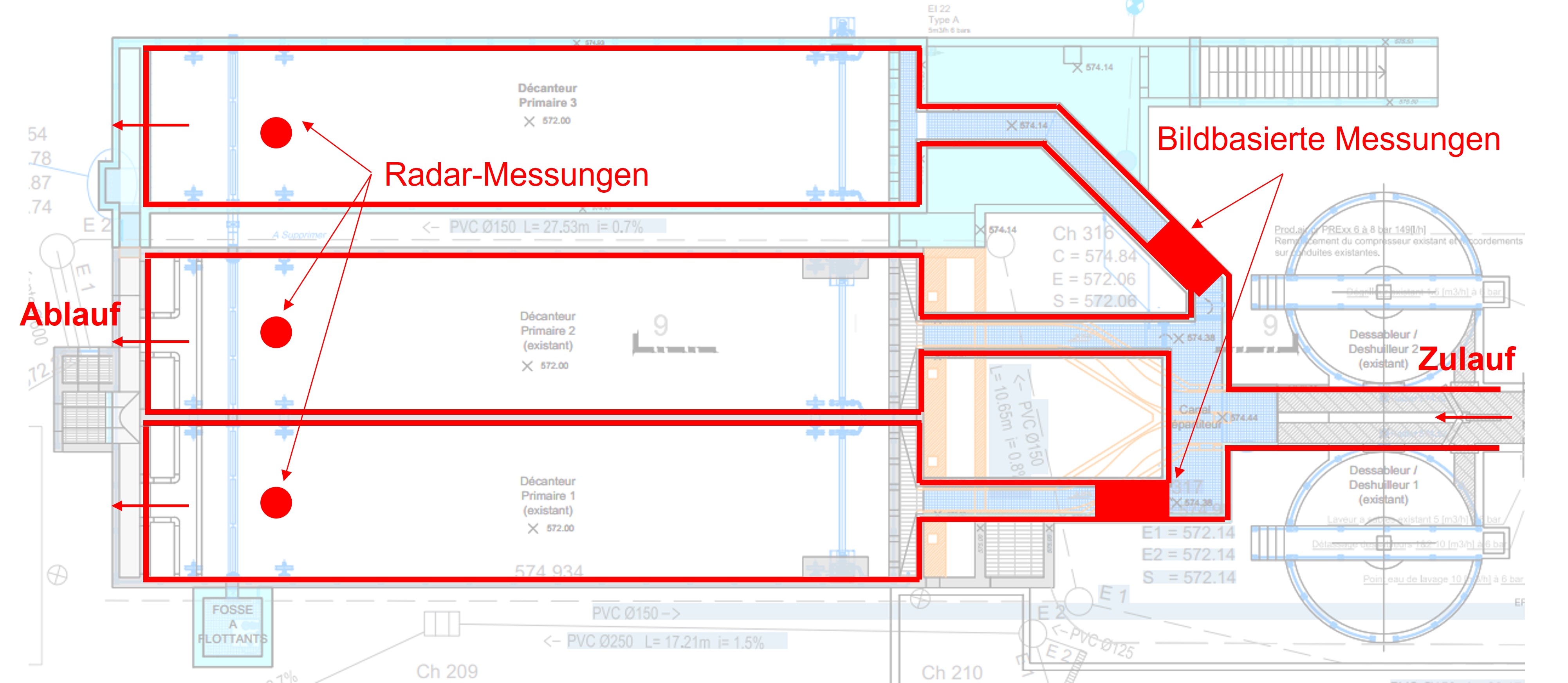

In a joint project with HOLINGER AG and Photrack AG, TK CONSULT AG validated results of 3D-CFD simulations performed for the optimization of a distribution structure.

Read Article

Pirmin Ebner, 06. April 2022

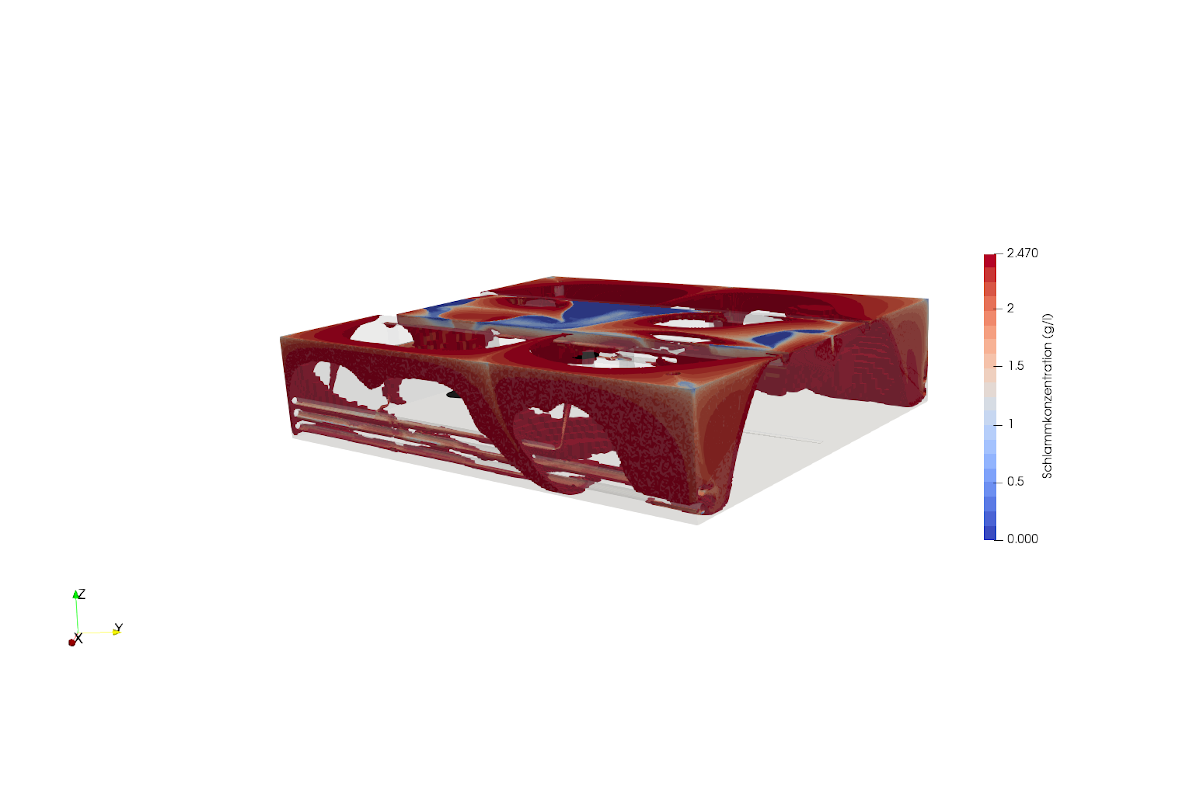

TK CONSULT AG, HOLINGER AG as well as HOLINGER Ingenieure GmbH (members of the HOLINGER group) was invited to present at the "7. Expertenforum Regenüberlaufbecken" of the DWA-Landesverband Baden-Württemberg in Stuttgart on the subject of "Optimisation of a rainwater basin using 3D-CFD simulation - practical example of planning and implementation steps".

Read Article

Mattias Deller, November 3, 2021

Increase of the intake- and cleaning capacity of a rain basin and checking the functionality during rainy weather condition

Read Article

Mattias Deller, June 15, 2021

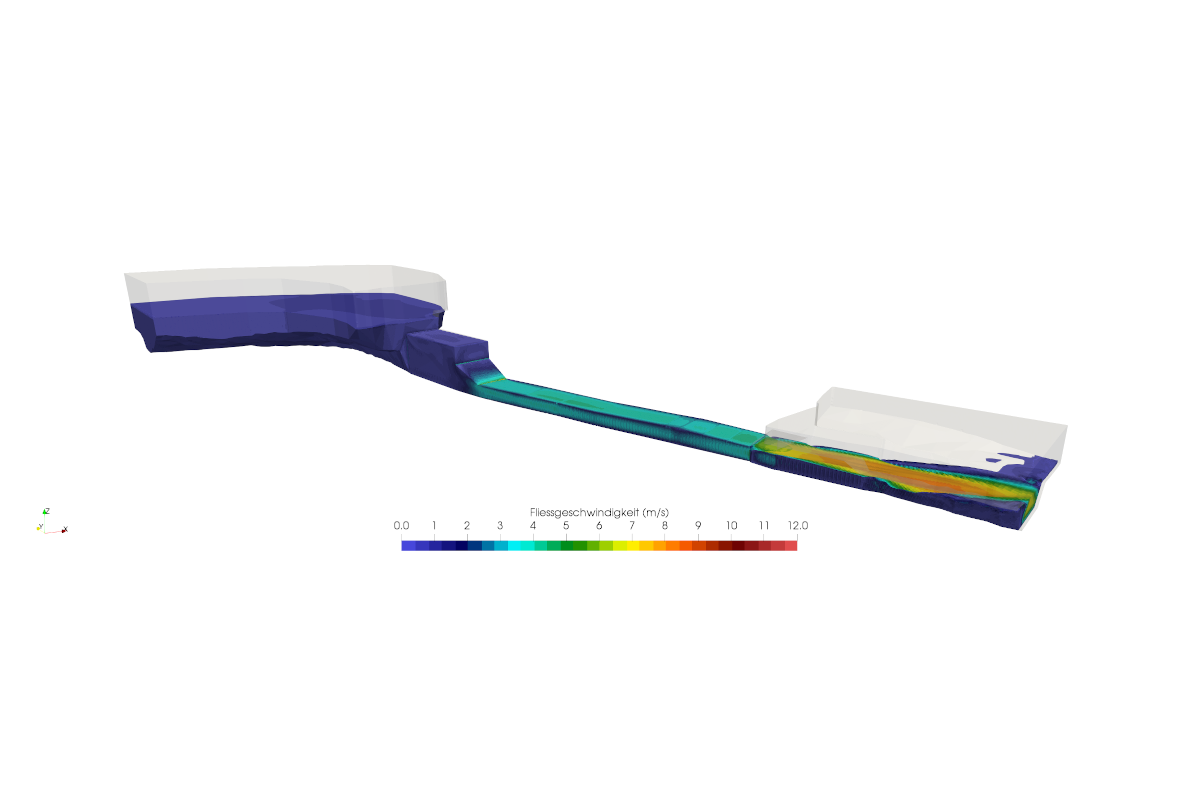

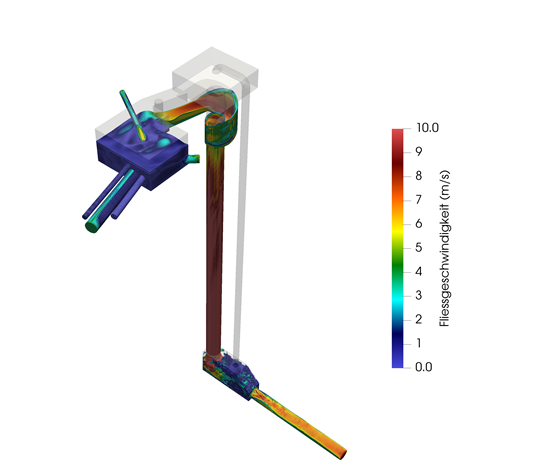

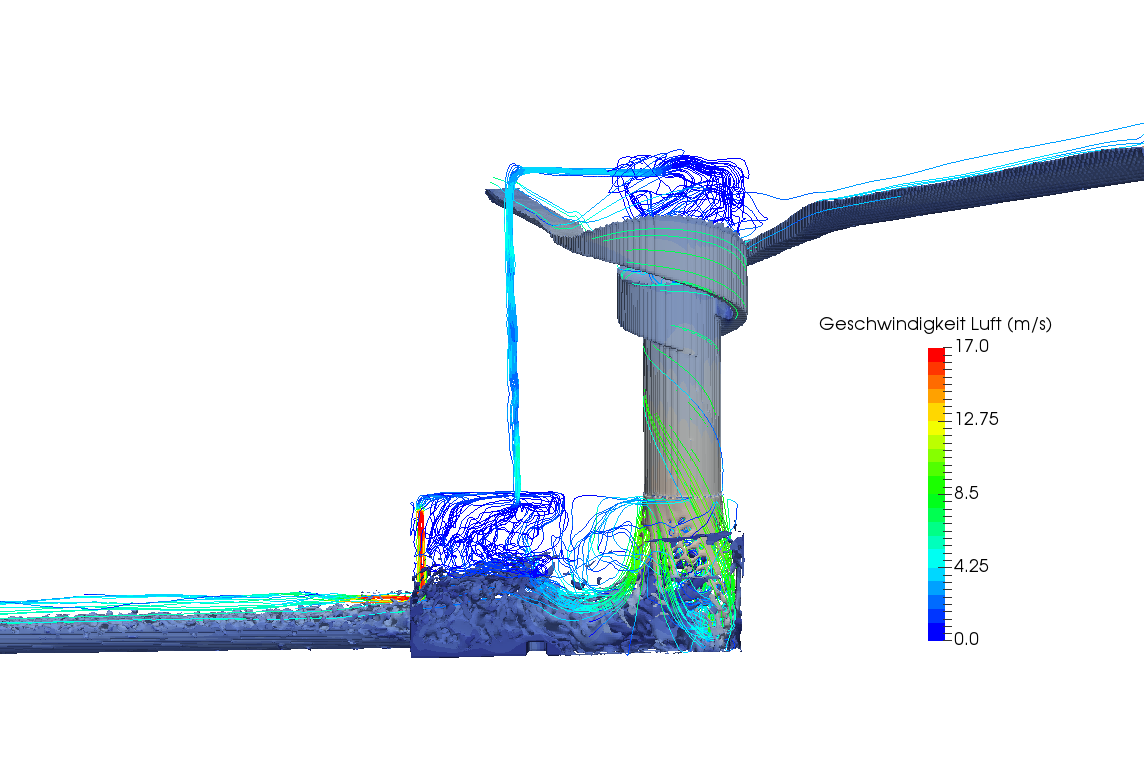

Hydraulic capacity validation of a vortex dropshaft with a fall height of 68 m using 3D-CFD simulations

Read Article

Matthias Deller, April, 9th 2021

TK CONSULT AG will give a presentation on 20th of April 2021 at the online VSA-Symposium on "DIGITIZATION IN CONSTRUCTION, OPERATION AND MAINTANENANCE OF DRAINAGE SYSTEMS" The instrument of 3D CFD simulations in urban drainage systems is presented.

Read Article

Mattias Deller, 22. February 2021

Hydraulic testing of the renovation work on a rainwater basin and the construction of a new drop shaft using a 3D-CFD simulation.

Read Article

Mattias Deller, 17 August 2020

Hydraulic evaluation and optimization of a union drop shaft

Read Article

Mattias Deller, 20. Mai 2020

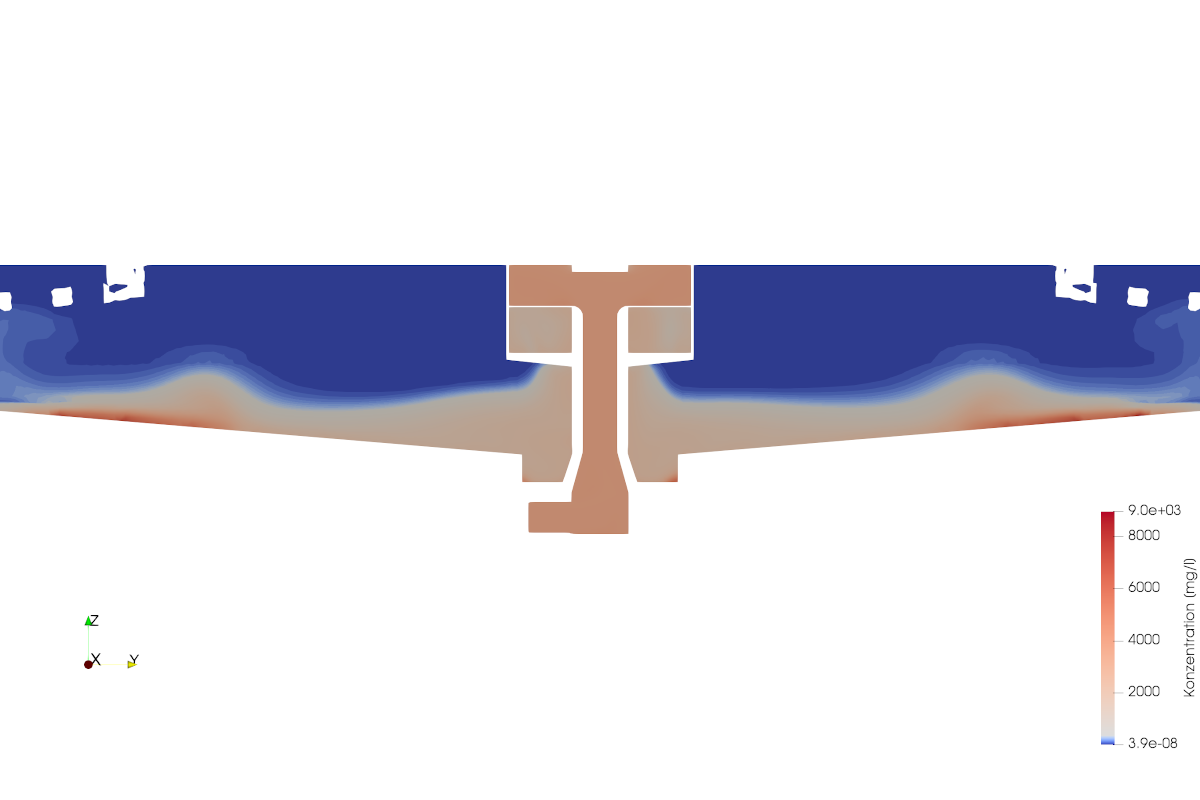

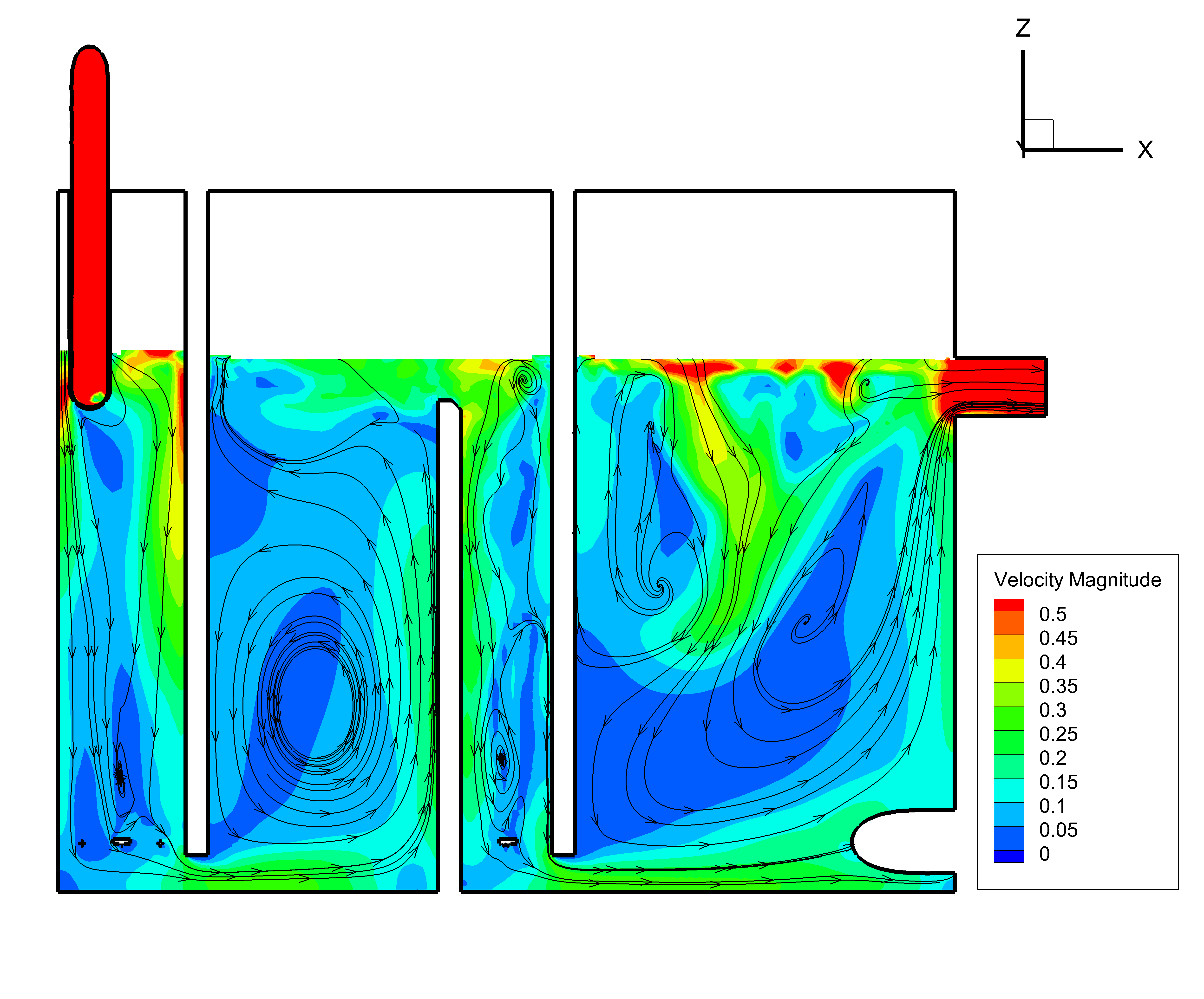

Optimization of the residence time of an ozonation reactor taking into account fumigation and tracer concentration

Read Article

Deller Mattias, June 14, 2019

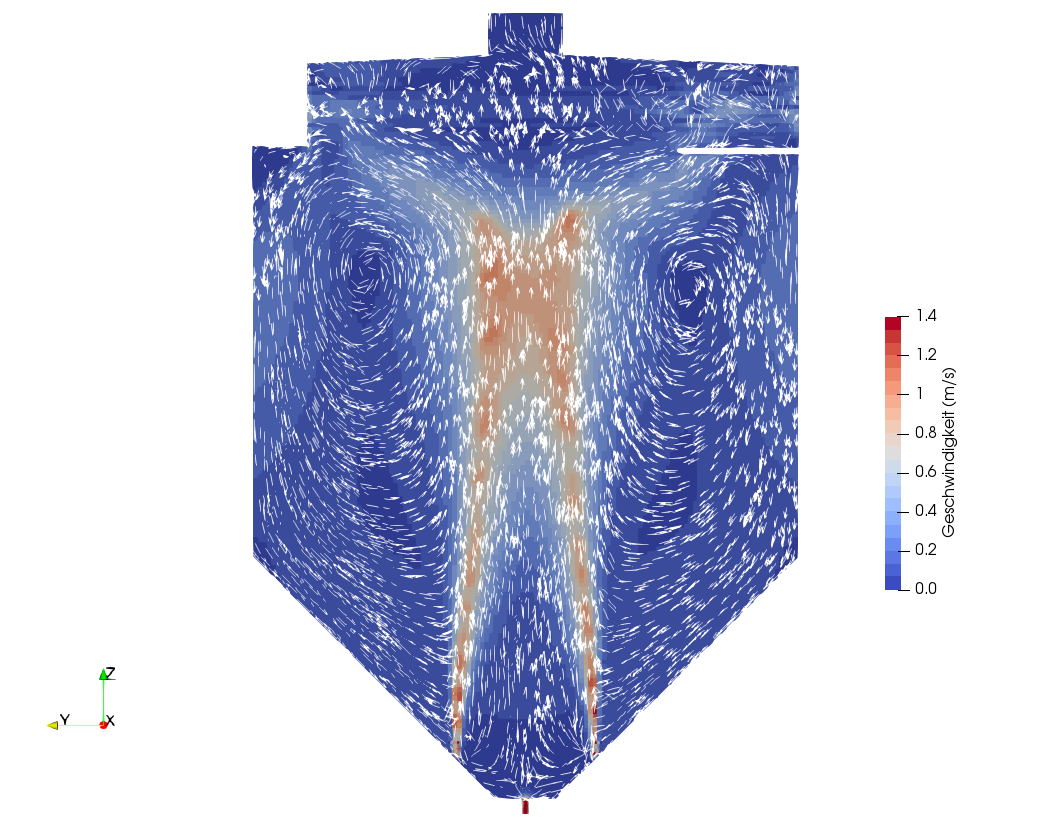

Investigation of the mixing performance in a digestion tank for different gas injection configurations.

Read Article

Mattias Deller, 15. April 2019

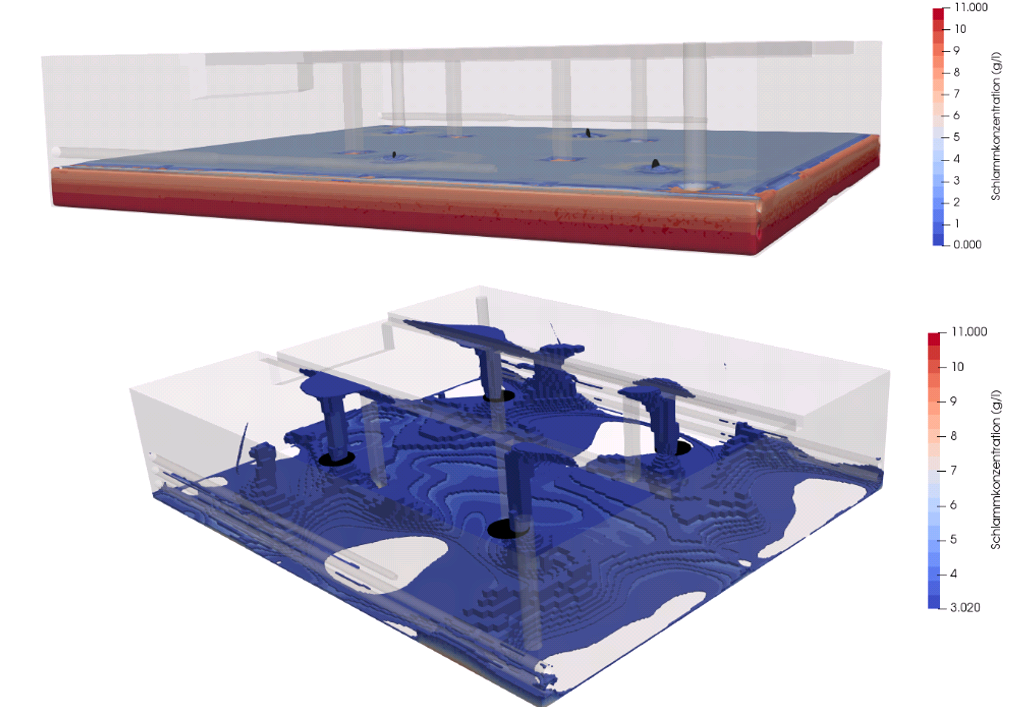

Sludge mixing optimization in a SBR using different stirrer configurations.

Read Article

Steffen Corbe, 18. February 2019

3D-CFD-simulations for the verification and optimization of a vortex dropshaft with two-way inflow.

Read Article

Mattias Deller, 12. September 2018

The retention time in a fresh water tank has been modeled, using a thermo - hydraulic approach. It could be shown that the steel walls heated by the sun influence the circulation inside the water tank and that compared to a purely hydraulic simulation different retention times are to be expected.

Read Article

Steffen Corbe, 07. Februar 2017

HOLINGER SA in Luxembourg invited their customers to a customer event staged at BIODIVERSUM in the "Haff Réimech" nature reserve. Steffen Corbe spoke on 3D CFD simulation in water management (Updated slides in German)

Read Article