3D-CFD simulation of an ozonation reactor

Mattias Deller, 20. Mai 2020

Optimization of the residence time of an ozonation reactor taking into account fumigation and tracer concentration

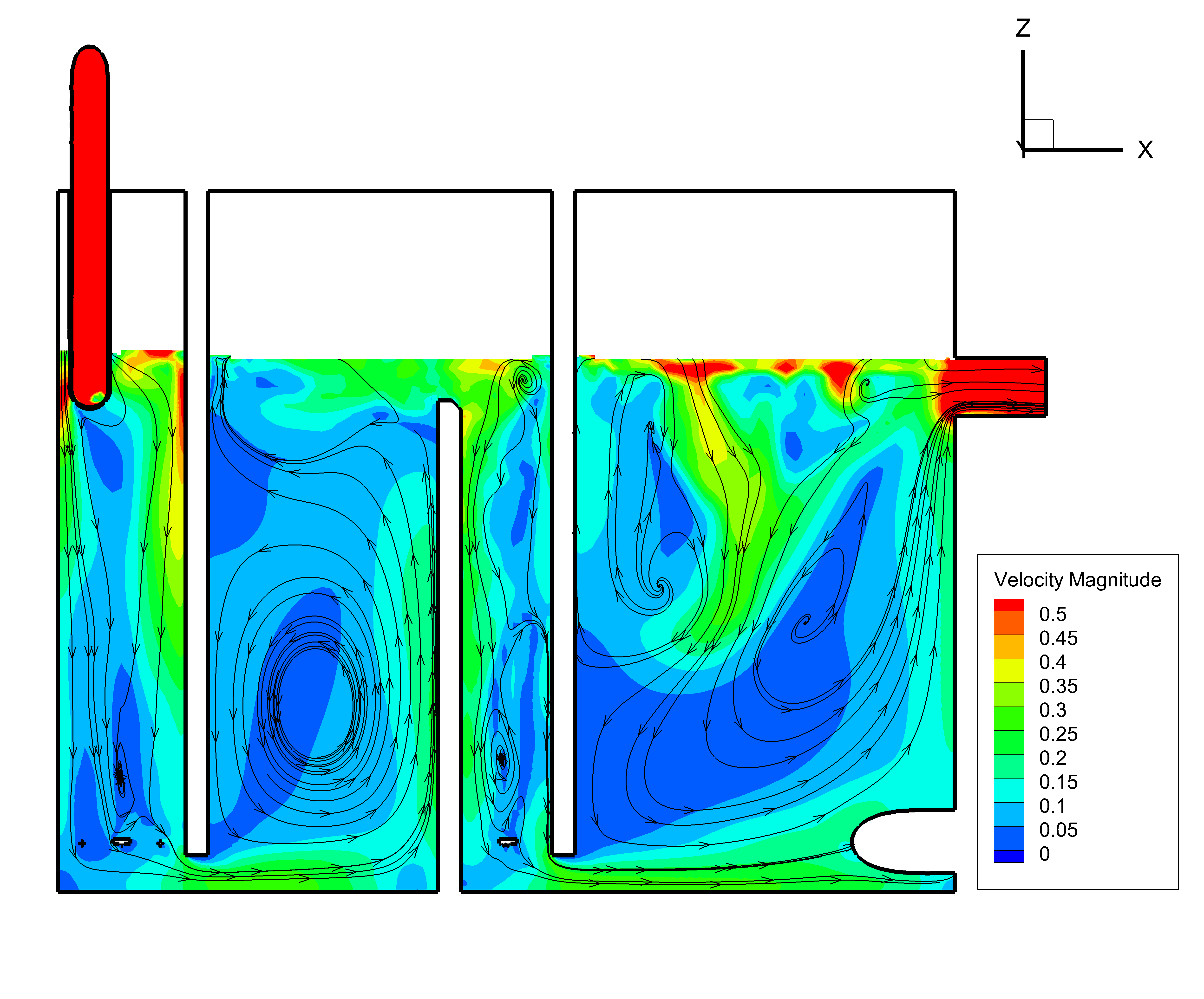

The ozonation reactor is the last cleaning stage of a wastewater treatment plant. The main purpose is to oxidize and break up organic micropollutants such as drugs, chemicals or cleaning agents. The efficiency of the ozonation mainly depends on the residence time of the wastewater in the ozonation reactor and the mixing with the ozone. If the residence time is too short, not all micropollutants are broken up. Therefore, the performance strongly depends on the flow conditions in the reactor. The investigated ozonation reactor does not show the desired treatment performance during rain events.

The operator of the reactor investigated the residence time using an on-site tracer experiment. They observed the concentration peak at the outflow to early, compared to the theoretical optimal residence time. Furthermore the concentration peak decreased very slowly after observing the concentration Peak. This indicates a hydraulic short circuit and the presence of larger dead water zones.

In order to better understand the current state and to optimize the reactor configuration, TK CONSULT AG was commissioned to carry out 3D-CFD simulations taking into account 2-phases (water and gas). In a first step, the goal was to calibrate the numerical 3D-CFD model of the ozonation reactor based on the tracer test. The simulated concentration curve at the outflow of the reactor showed a good agreement with the measured concentration curve from the tracer test. Based on the visualized 3D-CFD simulation results, measures were taken to optimize the flow conditions in the reactor. The measures included an increase of the flow path and a decrease of dead water zones by using additional partition walls and flow straighteners in different chambers of the reactor. The improvement of the flow conditions resulted in a tracer concentration curve with a significantly lower and delayed peak. Based on the 3D-CFD simulations the client was able to quickly identify the problem areas and improve the reactor at low cost.